Contamination: What's The Risk?

Contamination is the presence of unwanted and potentially dangerous substances that can pollute your products; it can be anything you don’t want or don’t expect to be present in the final product.

Contamination falls into one of three categories…

Physical

DUST, FIBERS, SKIN CELLS, PARTICLES, STATICALLY CHARGED PARTICLES

Chemical

RESIDUES, GASSES, MOLECULES

Microbiological

BACTERIA, YEAST, MOLD, POLLEN

Contamination can result in...

Inferior Quality

If a small particle of contamination affects, for example, how a microchip works it can result in the final product being faulty or reducing its effectiveness.

Rejected goods

A product recall puts your company’s brand and reputation at risk, sometimes to an irreparable degree.

Quarantined batches

One microbe can threaten the whole batch, leading to it being quarantined, scrapped, or requiring a full company shutdown.

Product yield impact

Contamination has a negative impact on product yields and overall profitability.

Health and safety issues

Contaminated environments and products pose a health and safety risk to employees and customers.

Hospital-acquired infections

Contamination in healthcare environments increases the risk of hospital-acquired infections such as MRSA.

Sources & Threats...

personnel

Humans can generate 5-10 million skin, hair, and dirt particles every minute. Humans create additional, dangerous particulate contamination through motion, and carry it with them into critical areas.

The Facility

The facility itself can introduce contamination. This can include contamination such as debris, dust, and powders from manufacturing processes, tools, and machinery.

Atmosphere

Airborne contamination should not be ignored. Contaminants such as mold spores, allergens, and other invisible particles in the air may pose a threat to critical areas.

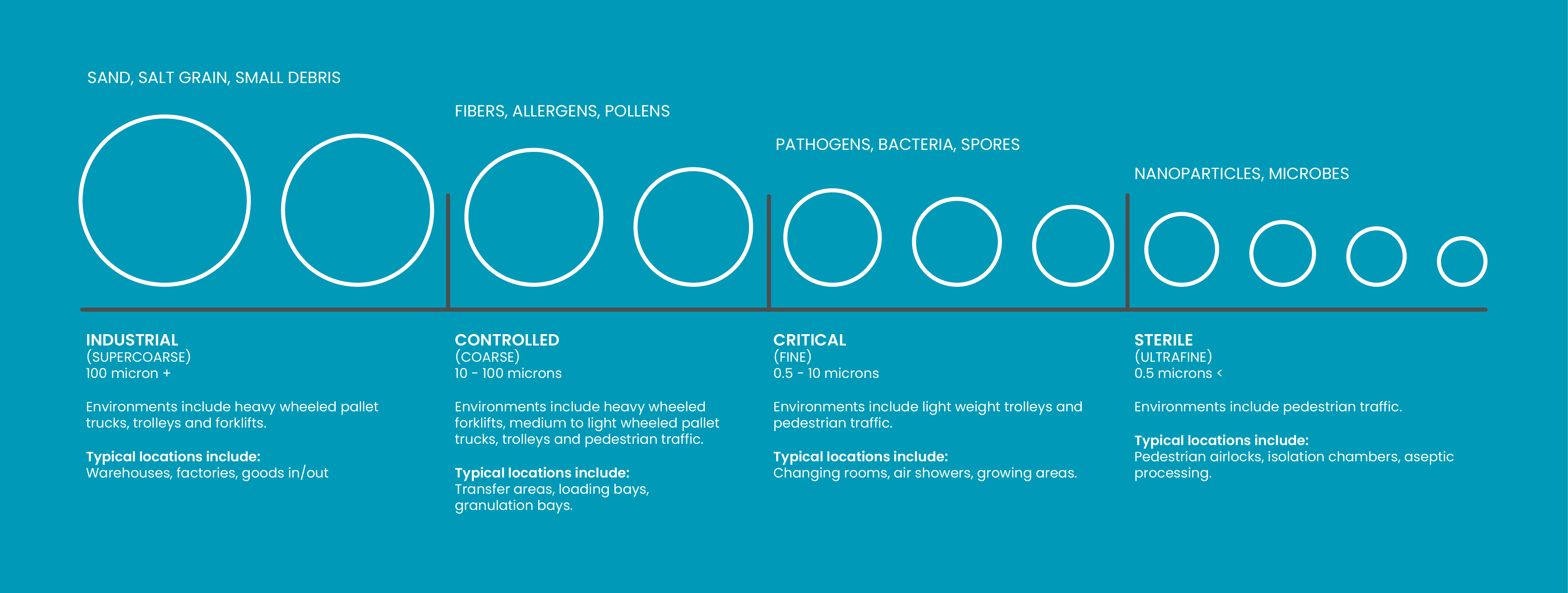

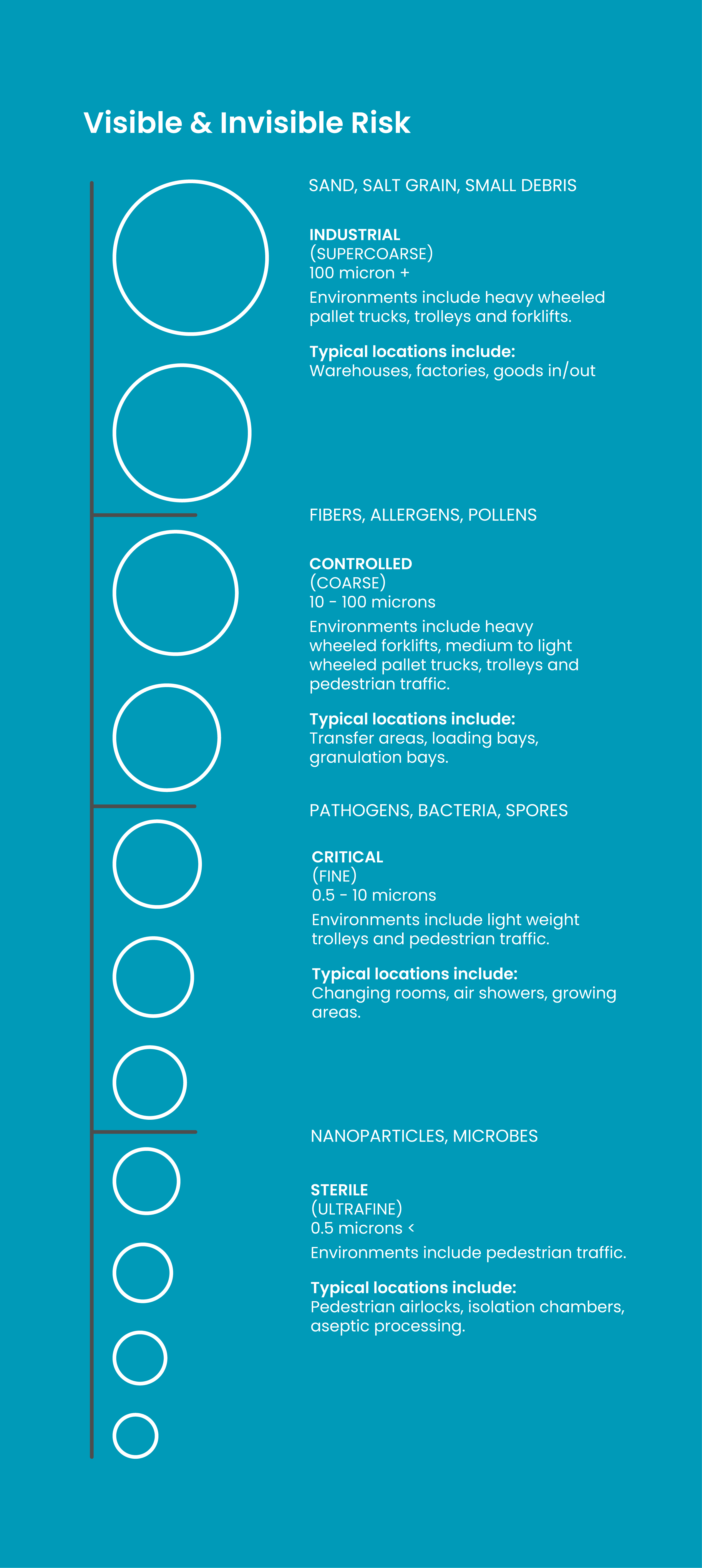

Visible and Invisible Risk

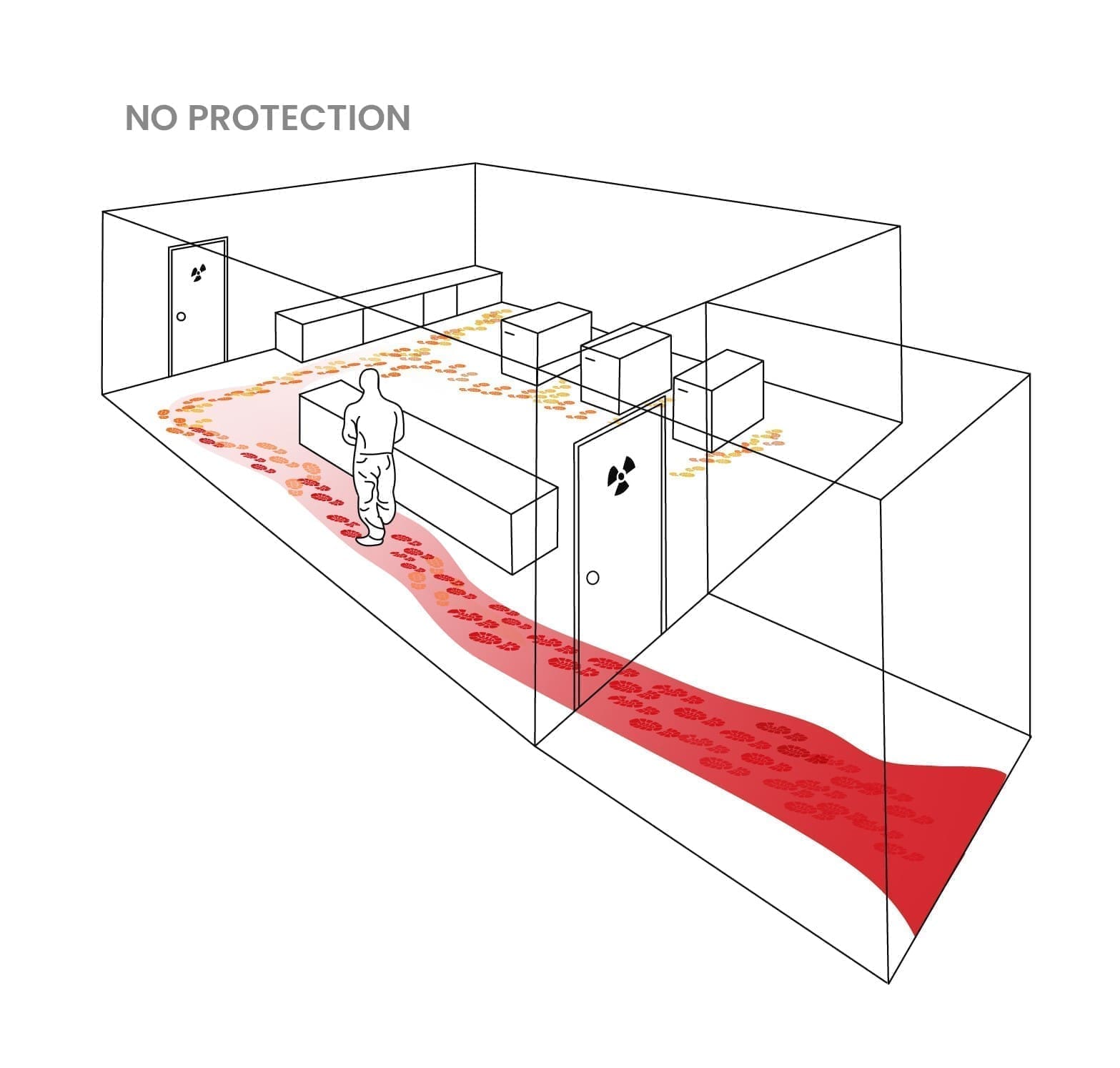

Don't Ignore the Floor!

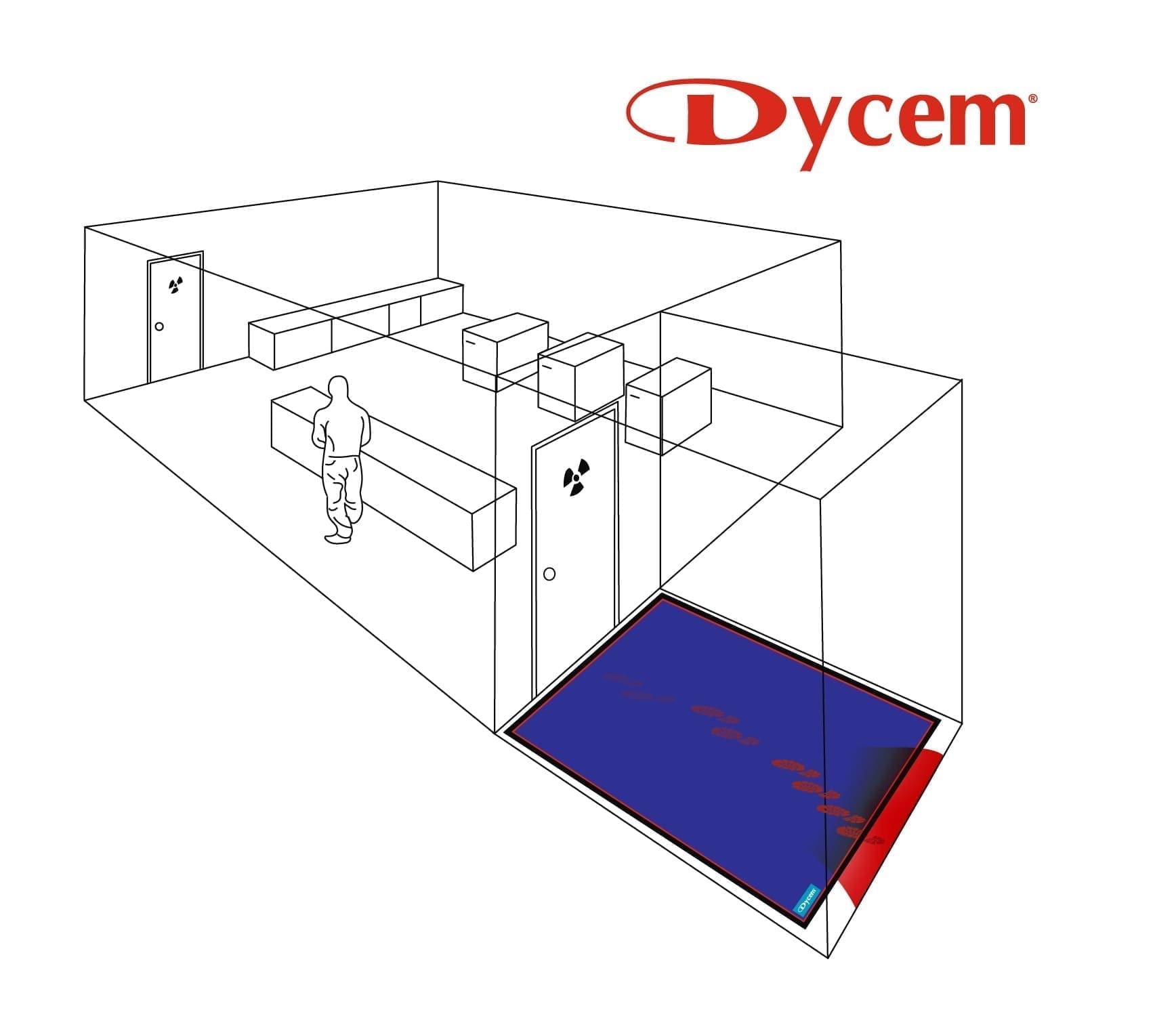

80% of contamination enters controlled environments via the floor. Therefore, contamination control is vital to prevent contamination and cross-contamination at the floor level to protect your environment. Without contamination control, floor-level contamination can be redistributed into the air, by the movement of bodies through the environment or airflow.

In some cases, implementing measures to reduce the risk of contamination in critical areas is a statutory requirement. Regulatory bodies such as the FDA (Food and Drug Administration) and professional auditing teams using risk management systems, all recognize the importance of contamination control at the floor level.

Ensuring that the unseen doesn't compromise the unbeatable quality of your products.

Did you know?

Dycem is the most effective solution for contamination control at the floor level, it attracts, captures, and retains up to 99.9% of contamination from shoes and wheels, and up to 75% of airborne contamination.